Stainless steel is an alloy comprised of elements such as aluminum, carbon, iron, molybdenum, and silicon, with a minimum of 10.5% chromium. The chromium creates a thin layer of oxide on the surface which prevents corrosion. There are 3 types of stainless steel: austenitic, ferritic, and martensitic, each of which are identified by their microstructure. Stainless steel is extremely strong and 100% recyclable; most “new” stainless steels often contains up to 50-80% recycled material.

Stainless steel is low maintenance, resists corrosion, and its strength makes it versatile to be used as bars, plates, sheets, and tubing in both domestic and industrial settings. It’s extremely popular in the food industry, as the metal doesn’t affect the flavors.

Duplex alloys are comprised of a two-phase microstructure that consists of grains of austenitic and ferritic stainless steel. Duplex alloys have the advantage of being twice as strong as regular stainless steel. These alloys have lower nickel and molybdenum contents, and because of this, duplex alloys can offer lower costs in times of high alloy surcharges.

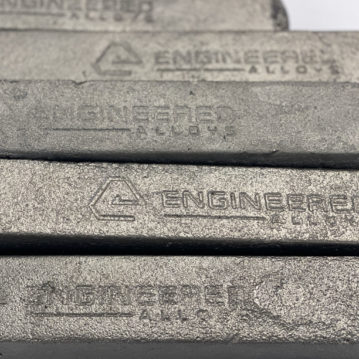

Engineered Alloys offers a variety of stainless steel & duplex alloys to meet our clients’ needs. Contact us today to request a quote and learn more about our products!